- business background:

Coal chemical industry wastewater contains large amounts of toxic and harmful substances such as phenol, cyanide, oil, and ammonia nitrogen. The CODcr in comprehensive wastewater is generally around 5000mg/l, and the ammonia nitrogen is between 200 and 500mg/l. The organic pollutants contained in the wastewater include phenols, polycyclic aromatic compounds, and heterocyclic compounds containing nitrogen, oxygen, and sulfur. It is a Typical industrial wastewater containing refractory organic compounds.

- Introduction to commonly used coal chemical wastewater treatment processes:

At present, the domestic technology for treating coal chemical wastewater mainly uses biochemical methods. Biochemical methods have a good effect on removing phenols and benzene substances in wastewater, but they are not effective in removing quinolines, indoles, pyridines, carbazoles, etc. The treatment effect of refractory organic matter is poor, making it difficult for the CODcr of external drainage in the coal chemical industry to reach the first-level standard.

At the same time, coal chemical wastewater has the characteristics of high chroma and turbidity after biochemical treatment (because it contains various chromophores and auxochromophore organic matter, such as 3-methyl-1,3,6-heptatriene, 5 -Norbornene-2-carboxylic acid, 2-chloro-2-norbornene, 2-hydroxy-benzofuran, phenol, 1-methanesulfonyl-4-methylbenzene, 3-methylbenzothiophene, Naphthalene-1,8-diamine, etc.).

- Features of our company’s coal chemical wastewater treatment process:

The coal chemical industry wastewater treatment process route basically follows “physical and chemical pretreatment + A/O biochemical treatment + physical and chemical advanced treatment”, which is briefly introduced below.

- Physical and chemical preprocessing

Commonly used methods for pretreatment: oil separation, air flotation, etc.

- Biochemical treatment

- Anaerobic biological method

A technology called upflow anaerobic sludge bed (UASB) is used to treat coal chemical wastewater. The reactor used in this method was successfully developed by G. Lettinga of the Netherlands in 1977. The wastewater passes through the reactor with a sludge layer at the bottom from bottom to top, where most of the organic matter is converted into CH 4 and CO by microorganisms . 2 in the upper part of the reactor. Equipped with a three-phase separator to complete the separation of gas, liquid and solid phases.

In addition, activated carbon anaerobic expanded bed technology is also used to treat coal chemical wastewater. This technology can effectively remove phenols and heterocyclic compounds in wastewater.

- Anaerobic-aerobic combined biological method

After coal chemical industry wastewater undergoes anaerobic acidification treatment, the biodegradation performance of organic matter in the wastewater is significantly improved, making the subsequent aerobic biological treatment CODcr removal rate reach more than 90%. Among them, the removal rates of naphthalene, quinoline and pyridine, which are more difficult to degrade organic compounds, are 67%, 55% and 70% respectively, while the removal rates of these organic compounds in general aerobic treatment are less than 20%.

- Advanced Oxidation Technology

Since the organic matter in coal chemical wastewater is complex and diverse, refractory organic matter such as phenols, polycyclic aromatic hydrocarbons, and nitrogen-containing organic matter account for the majority. The presence of these refractory organic matter seriously affects the effect of subsequent biochemical treatment.

Advanced oxidation technology generates a large amount of HO. Free radicals in wastewater. HO. Free radicals can non-selectively degrade organic pollutants in wastewater into carbon dioxide and water. Advanced oxidation technology can be divided into homogeneous catalytic oxidation method, photocatalytic oxidation method, multiphase wet catalytic oxidation method and other catalytic oxidation methods.

The catalytic oxidation method can be used in the early stage of the coal chemical wastewater treatment process to remove part of COD and enhance the biodegradability of wastewater. However, there are problems such as large consumption and uneconomical operation. Therefore, this technology can be used in subsequent advanced treatment units to obtain Better economy and degradation effect.

- adsorption method

Since the solid surface has the ability to adsorb solutes and colloids in water, when wastewater passes through solid particles with a large specific surface area, pollutants in the water are adsorbed to the solid particles (adsorbent), thereby removing pollutants. This method can achieve good results, but it has problems such as large amount of adsorbent, high cost and secondary pollution. It is generally suitable for small-scale sewage treatment applications.

- coagulation sedimentation

The sedimentation method is a process that utilizes the settleability of suspended matter in water to sink under the action of gravity to achieve solid-liquid separation. Its purpose is to remove suspended organic matter to reduce the organic load for subsequent biological treatment.

Coagulants such as aluminum salts, iron salts, polyaluminum, polyiron and polyacrylamide are usually added during production to enhance the precipitation effect. The influencing factors of this method include the pH of the wastewater, the type and dosage of the coagulant, etc.

- Our company’s coal chemical wastewater treatment indicators:

According to the “Coking Chemical Industry Pollutant Emission Standard” GB16171-2012, volatile phenol ≤ 0.3mg/L; cyanide ≤ 0.2mg/L; independent coking enterprises: volatile phenol ≤ 0.1mg/L; cyanide ≤ 0.2mg/L;

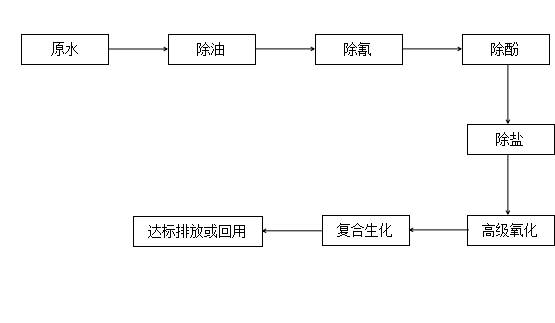

- Process flow block diagram:

- Typical projects:

Hebei ***Chemical Co., Ltd. is a company specializing in the recovery of mixed phenols produced in the coal chemical industry. The components of the wastewater after phenol recovery are relatively complex. The wastewater contains phenol, cyanide, oil, ammonia nitrogen, salt, etc.; the wastewater has complex components. , our company first removes cyanide, then recovers phenol and salt, and then improves the biodegradability of wastewater through advanced oxidation. After biochemical treatment, the cyanide content in the effluent is less than 0.1mg/l, and the phenol content is less than 0.3mg/l; water After the membrane treatment process, it is all recycled into the production circulating water.

| Indicator item | raw water | Phenol recovery | Phenol, cyanide cracking | Water discharge after biochemical treatment |

| COD (mg/L) | 5,000 | 5,000 | 500 | 100 |

| Ammonia nitrogen (mg/L) | 500 | 600 | 300 | 2 |

| Phenol (mg/L) | 500 | 2 | 0.15 | 0.1 |

| cyanide | 100 | – | 0.15 | 0.1 |