- Introduction to chemical separation customization

Hubei Sanli Liquidambar Technology Co., Ltd. has established a distillation engineering technology research center in cooperation with Tianjin University. It is mainly engaged in the research and development of cutting-edge distillation technology, process control and diagnostic technology, and provides customers with sustainable development of advanced distillation technology services. The technical team of the center has solid theoretical foundation and rich experience in technology development, engineering construction and on-site operation. The company is dedicated to providing the most advanced and complete separation process technology to domestic and foreign customers.

The core technology of Hubei Sanli Liquidambar Technology Co., Ltd. is high-efficiency mass transfer separation equipment (packing, trays). The company focuses on the research and development, design and production of mass transfer equipment, and provides complete solutions for various separation problems; and is committed to new The research and development of chemical separation technology can achieve the purpose of saving investment in construction equipment and saving production costs for chemical production enterprises.

In terms of conventional chemical separation technology, Hubei Sanli Liquidambar Technology Co., Ltd., with the technical support of experts and professors from Tianjin University, can provide users with one-stop technical services such as experiments, process calculations, design, manufacturing, installation guidance, and start-up. It has successfully built and renovated towers for enterprises in industrial fields such as oil refining, air separation, chemical fertilizers, light industry, coal chemicals, fine chemicals, pharmaceuticals, and food. And it has won praise from the majority of users for its superb technology, reliable quality, first reputation and first-class service.

In terms of new chemical separation technology, Hubei Sanli Liquidambar Technology Co., Ltd. focuses on developing new energy-saving chemical separation technologies to fully reduce the energy consumption of the separation process and improve thermodynamic efficiency. In multi-effect distillation, heat pump distillation, thermal coupling distillation, There are related engineering achievements in the fields of integration of distillation and other separation processes. Compared with conventional separation technology, the new separation technology can achieve a small footprint and reduce energy consumption by about 30 to 40%.

The company has complete sets of processes in the following fields:

Refinery atmospheric and vacuum system tower capacity expansion and reconstruction design

Capacity expansion and reconstruction design of catalytic cracking main fractionator and absorption stabilization system

Refining and Reforming Heavy Aromatics Thermal Coupling Separation Technology (Patented)

- Urea exhaust gas cooling and washing system (patented)

- Refining C3, C4, C5 separation technology

- Methyl ethyl ketone separation system

- High-purity methylal and dimethyl carbonate reactive distillation system (patented)

- Development of aqueous product recovery process for coal-to-liquids plant

- H2S refining system (patented)

- Styrene distillation system

- Ethylene oxide and propylene oxide separation system

- Aniline separation system

- MDI condensation, photochemical, distillation system

- TDI separation system

- Nitrobenzene and nitrochlorobenzene separation system

- High purity silicone separation system

- Reforming Aromatics Separation System

- Ethylbenzene-styrene separation system

- Ethylene oxide-ethylene glycol unit

- C4, C5, C6 separation device

- Special solvent oil separation device

- Hydrocracking gasoline and diesel refining tower

- Sewage stripping device

- Ethylene industry

- Fertilizer industry

- air separation industry

New chemical separation technology:

- multi-effect distillation

Multi-effect distillation is a heat integrated distillation system that uses the latent heat of the high-pressure tower overhead steam to provide heat to the reboiler of the low-pressure tower, and the high-pressure tower overhead steam is condensed at the same time. At present, our company has multiple sets of mature devices of this separation technology in the fields of methylal, methanol separation, solvent recovery, fusel oil recovery and other fields.

- heat pump distillation

A system that transfers heat from a low level to a high level through external work is called a heat pump system. A heat pump raises the temperature of low-temperature heat energy to a level where it can be utilized at the expense of consuming a certain amount of mechanical work. Since the available heat obtained far exceeds the energy input into the system, energy can be saved. The starting point of heat pump distillation is to increase the level of part of the energy in the distillation process for its own reboiler heating needs. At present, our company has reached a friendly cooperation agreement with Shaangu to jointly develop and expand the heat pump distillation technology business.

- Thermal coupled distillation

Thermal coupling is a process structure that directly carries out material transportation and energy transfer through the reciprocal flow contact of gas and liquid phases. That is, a liquid phase stream is led from a certain tower to directly serve as the top reflux of another tower, or the gas phase is led out. The stream is directly refluxed as the gas phase at the bottom of another tower, thereby achieving direct thermal coupling. The most representative one is Petlyuk thermocouple distillation. This structure saves a condenser and a reboiler on the equipment, and due to the tower The degree of internal backmixing is reduced, and the thermodynamic efficiency of the separation process is improved to achieve energy saving effects. At present, our company has multiple sets of mature devices of this separation technology in the fields of industrial naphthalene separation, gasified phenol separation, cresol separation, fusel oil separation, C9C10 separation and other fields.

- Other distillation technologies

Our company continues to innovate in the field of chemical separation, and has established industry-university-research cooperation with universities and enterprises to conduct in-depth research and development of new distillation technologies such as molecular distillation, supergravity distillation, and capillary distillation.

- Product display

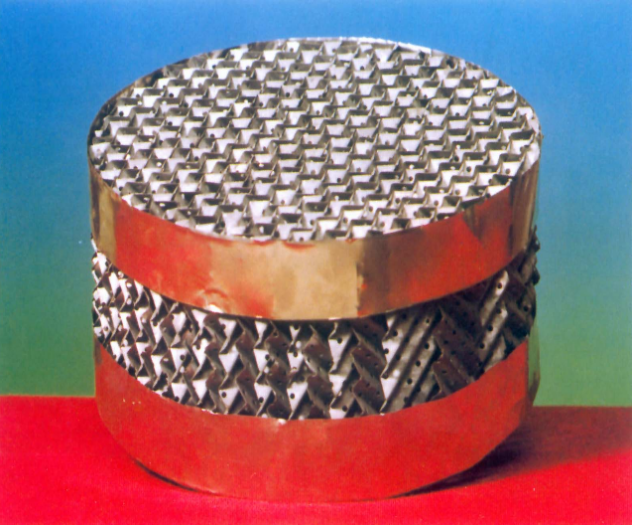

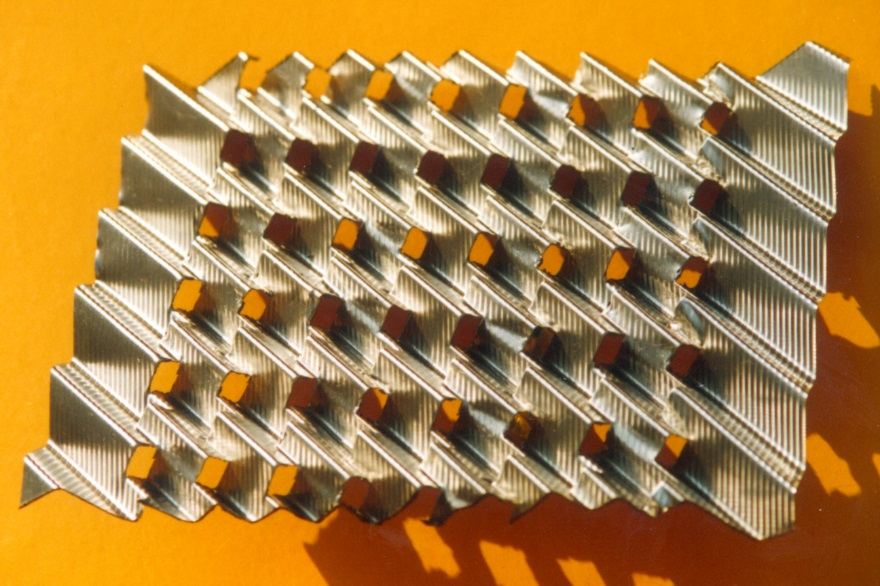

Orifice plate corrugated packing:

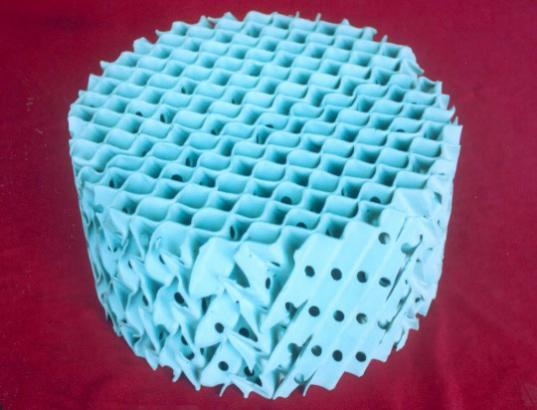

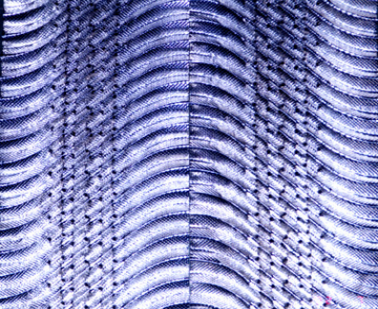

Plastic plate corrugated packing:  Ceramic structured packing:

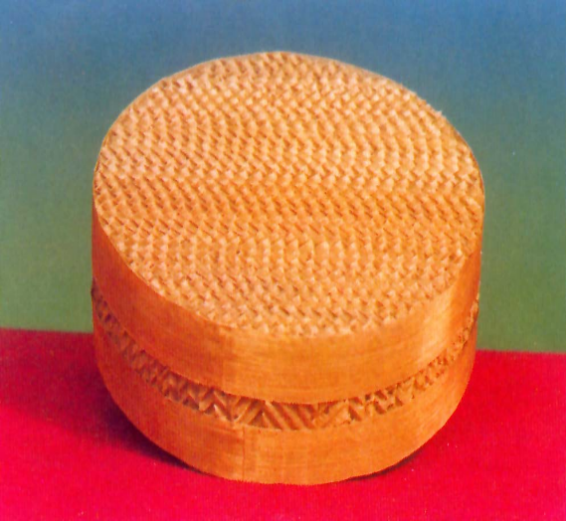

Ceramic structured packing:

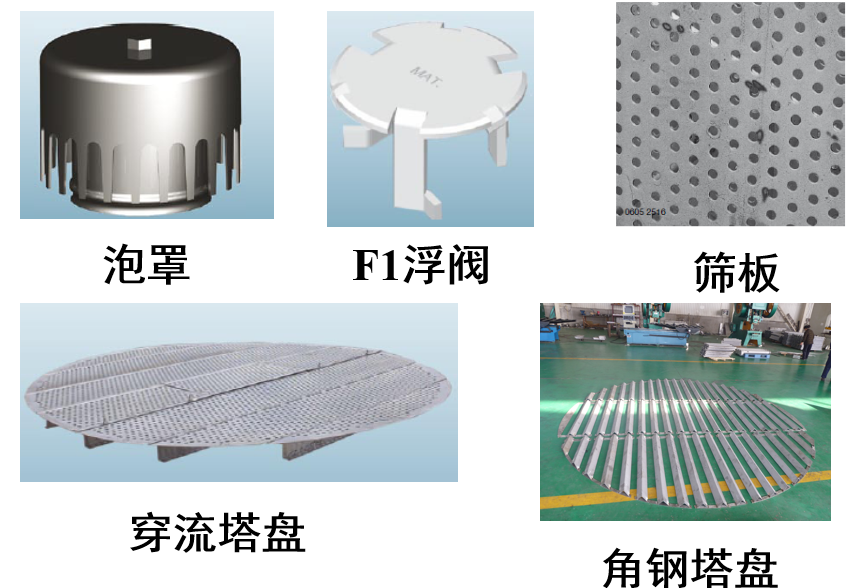

Regular products:

New type of packing – laminated corrugated packing: separation efficiency increased by 10%, flux increased by 20%, pressure drop reduced by 30%

New type of filler-bidirectional curved wave filler:

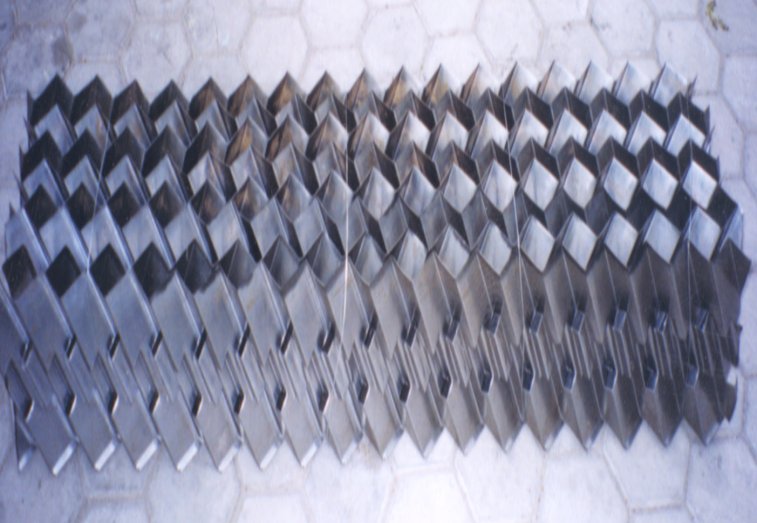

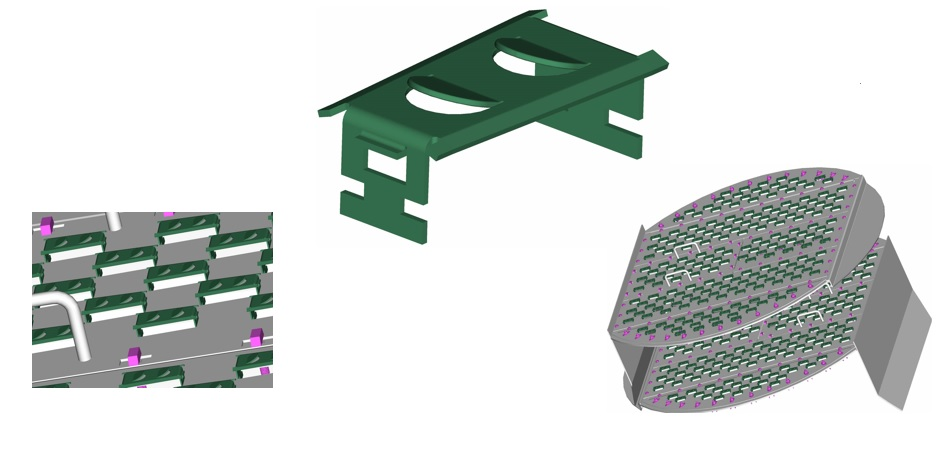

New internal parts – grille: light weight, low investment; strong resistance to dirt and blockage, high heat transfer efficiency; high stiffness, long life; pressure reduction is lower than Grich grille and angle steel tray.

New internal parts – nozzle liquid distributor: often used in washing towers, pressure reducing towers, pump reflux heat extraction sections and clean washing sections to enhance the heat transfer effect, reduce the filling height required for conventional heat exchange, and reduce the pressure drop across the tower. It is conducive to reducing pressure and deep pulling while reducing equipment investment.

New internal parts – trough-type oil collection tank or trough-disk distributor: multi-functional, low space occupation; anti-clogging, anti-entrainment; high elasticity, rising liquid level; suitable for flash evaporation, suitable for extraction; uniform gas distribution and liquid distribution uniform.

New internal parts – injection type guided trapezoidal float valve:

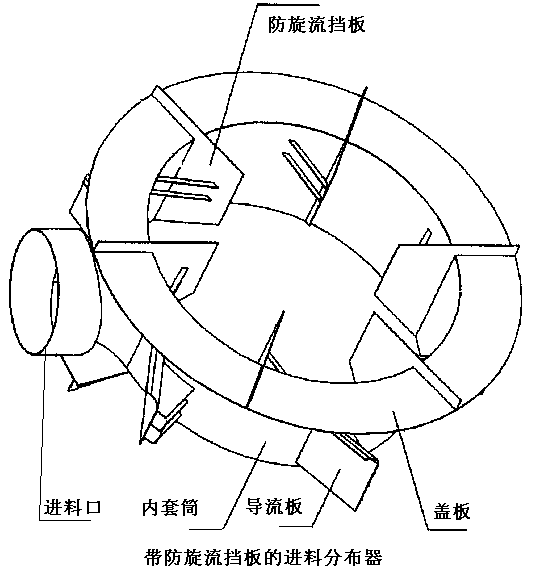

New internal parts-double tangential air intake distributor:

New internal parts – double-row blade air intake distributor:

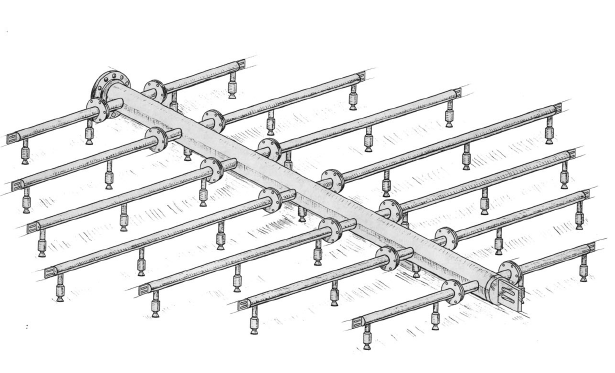

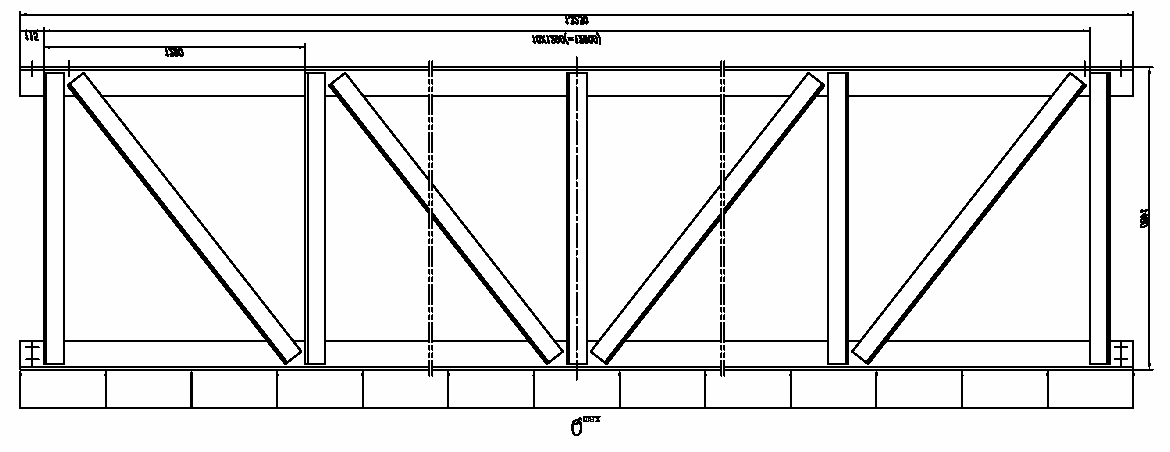

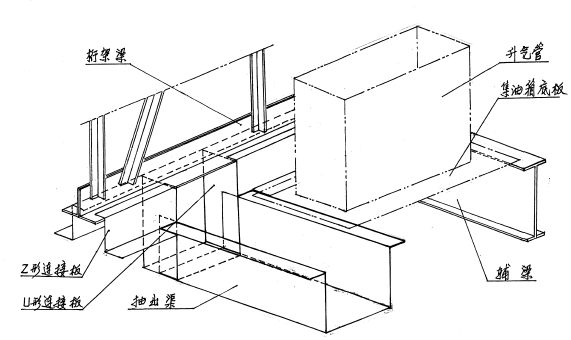

Internal parts – large tower internal parts support beam:

For more detailed chemical separation customization technical information, please contact us. Hubei Sanli Liquidambar Technology Co., Ltd. specializes in providing customized technical solutions for chemical separation.