- business background :

Wastewater containing phenolic substances comes from a wide range of sources and is highly harmful. Phenol-containing wastewater of different quantities and properties can be produced in industrial production processes such as resins, synthetic fibers, dyes, medicines, spices, pesticides, explosives, fiberglass, paints, disinfectants, floating agents, chemical reagents, etc.

Phenol-containing wastewater has a phenol concentration of 1,000 to 70,000 mg/l, and also contains pollutants such as oil, suspended solids, sulfide, ammonia nitrogen, and cyanide. If phenol-containing wastewater is discharged into water bodies without treatment, it will harm the reproduction and growth of aquatic organisms. Survive.

- Introduction to common treatment processes for phenolic wastewater:

- Extraction method: The extraction method uses solvent extraction, such as benzene, toluene, ethers, and butyl acetate as extraction agents, or complex extraction agents (such as N503).

- Adsorption method: Commonly used is the use of activated carbon for adsorption to achieve the effect of reducing the phenol content in water.

- Ion exchange method: Commonly used is ion exchange resin adsorption, and the company’s unique solvent is used for resin regeneration and phenol recovery.

- Oxidation method: Oxidation methods include reagent oxidation, ozone oxidation, micro-electrolytic oxidation, photocatalytic oxidation, wet oxidation, ultrasonic/H 2 O 2 method, ClO 2 oxidation method, etc.; the specific process needs to be determined according to the actual situation.

- Biochemical method: Using phenol as a nutrient for microorganisms, the phenol content in wastewater is removed through the metabolic decomposition of the organism itself.

- Introduction to our company’s phenolic wastewater treatment technology:

Through practical demonstration in multiple engineering cases, our company can reduce the phenol content in the water to less than 5 mg/l by using a reasonable process optimization combination, and then reduce the phenol content in the water to less than 0.3 mg/l through biochemical treatment.

- Our company’s phenolic wastewater treatment technology treatment indicators:

According to the latest standard requirements of the “Petrochemical Industry Pollutant Emission Standard” GB31571-2015: the first-level emission standard for volatile phenol content cannot exceed 0.3mg/l. The third-level emission standard cannot exceed 0.5mg/l.

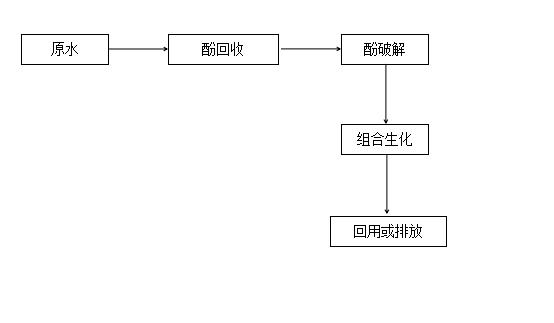

- Process flow block diagram:

- Typical projects

Anhui Anqing *** Co., Ltd. is a company specializing in phenol separation. The phenol content of the effluent is 8000mg/l. After phenol recovery, the phenol content in the wastewater is reduced to 5mg/l, and then cracked through advanced oxidation to improve the biodegradability of the wastewater. After passing the biochemical process, the recovered phenol in the effluent is reduced to less than 0.1mg/l.

| Indicator item | raw water | Phenol recovery | Phenol Crack | Water discharge after biochemical treatment |

| COD (mg/L) | 30,000 | 5,000 | 500 | 300 |

| Ammonia nitrogen (mg/L) | 1,500 | 600 | 300 | 5 |

| Phenol (mg/L) | 8,000 | 5 | 0.5 | 0.1 |