- Technology Introduction

Our company provides naphtha cutting, reforming C9 crude aromatic hydrocarbon separation, reforming C10 crude aromatic hydrocarbon separation and other crude aromatic hydrocarbon separation technologies. Our company’s crude aromatics separation process has the advantages of advanced process flow, high process operation flexibility, low process energy consumption, and high product yield.

Taking the separation of 60,000 tons/year C10 crude aromatics as an example, the high-boiling solvent product obtained has high aromatic content, strong solubility, low toxicity, small odor, high flash point, high boiling point, moderate volatilization speed, and stable chemical and physical properties. It has good leveling properties and does not contain chlorine and heavy metals/physics. It can exert high solubility especially in the later stages of evaporation, making the coating film smooth without orange peel and with good gloss. In addition, it can also be used as a cleaning agent for precision machinery and a pesticide emulsifier. It is an ideal solvent for the production of high-grade paints, coatings, thinners, inks, adhesives, petroleum additives and high-temperature reactions. It can also be used as an extraction agent for the production of hydrogen peroxide by the quinone method.

- Typical projects

60,000 tons / year C10 crude aromatics separation case

Processing capacity: 60,000 tons/year C10 crude aromatics

Annual operating time: 8,000 hours

Operation flexibility 70%-110%

Raw materials: C10 crude aromatics (distillation range analysis results)

| Weight percentage/% | Temperature/°C | Weight percentage/% | Temperature/°C |

| 0 | 191 | 50 | 208.5 |

| 5 | 193 | 55 | 211.5 |

| 10 | 195 | 60 | 214.5 |

| 15 | 196.5 | 65 | 218.5 |

| 20 | 198 | 70 | 225 |

| 25 | 199.5 | 75 | 234 |

| 30 | 201 | 80 | 248 |

| 35 | 202.5 | 85 | 270 |

| 40 | 204 | 90 | 295 |

| 45 | 206 | 95 | 330 |

Product solutions

| serial number | project | Specification | unit | Capacity |

| 1 | SA-1000 high boiling point solvent | Distillation range: 149-180ºC | t/a | 10000 |

| 2 | SA-1500 high boiling point solvent | Distillation range: 177-215ºC | t/a | 2000 |

| 3 | SA-1800 high boiling point solvent | Distillation range: 200-270ºC | t/a | 22000 |

| 4 | Methyl tetramethylbenzene enriched solution | 25%-30% | t/a | 16000 |

| 5 | SA-3000 high boiling point solvent | Initial boiling point: ≥270ºC | t/a | 10000 |

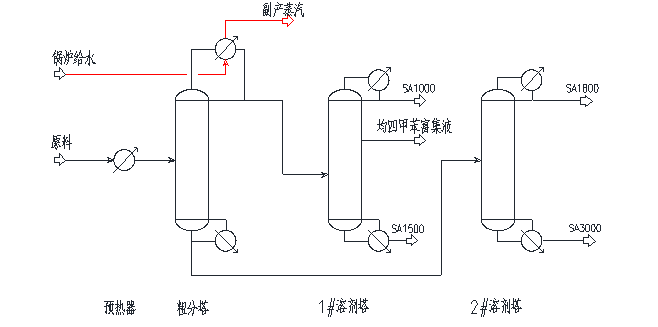

Process flow diagram

Project pictures