Wastewater treatment technology containing fusel oil

- Process introduction

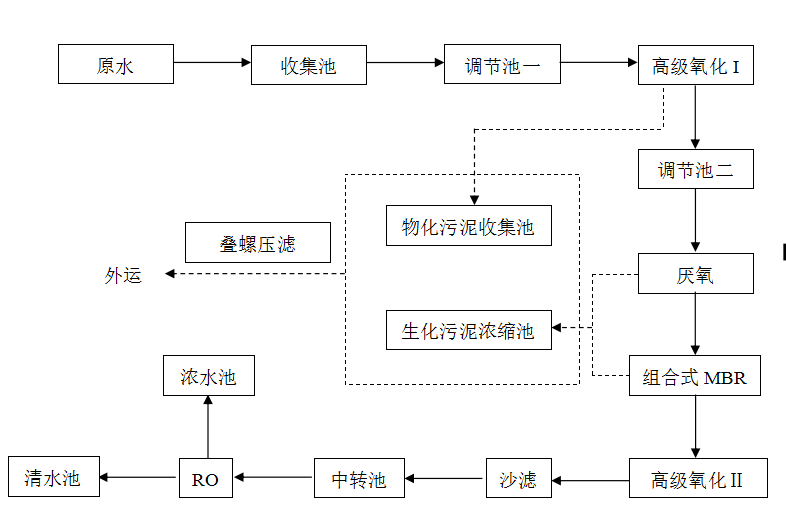

Our company’s fusel oil-containing wastewater technology adopts a two-step advanced oxidation combined with a composite MBR system. A brief introduction is as follows:

Step One: Advanced Oxidation I

Advanced oxidation I is a new type of wastewater treatment that uses Fe-Mn-Cu-C alloy material (DD catalyst) wastewater containing rare earth precious metals to undergo a series of electrochemical, physical and chemical reaction processes on its surface to treat its pollutants. technology. Using this method to pretreat wastewater can reduce the CODCr content in the wastewater, remove the color in the water, improve the biodegradability of the wastewater, and reduce the pollution load through coagulation.

Step Two: Advanced Oxidation II—Ozone Heterogeneous Catalytic Oxidation

Ozone heterogeneous catalytic oxidation technology is an advanced oxidation technology that generates a large number of strong oxidizing free radicals – hydroxyl radicals under the catalysis of precious metals. Hydroxyl radicals are very reactive, react quickly with most organic matter, and remove organic matter quickly and efficiently. Hydroxyl radicals can degrade pollutants in sewage that cannot be oxidized by ordinary oxidants. Moreover, hydroxyl radicals react with organic matter, and the organic free radicals generated in the reaction can continue to participate in the chain reaction of HO, or by generating organic peroxidation free radicals. After the base, further oxidative decomposition reaction occurs until it is degraded into the final products CO2 and H2O.

Membrane Bio-Reactor (MBR) is a new type of wastewater treatment system that organically combines membrane separation technology and biological treatment technology. Use membrane modules to replace the secondary settling tank at the end of traditional biological treatment technology, maintain a high activated sludge concentration in the bioreactor, increase the organic load of biological treatment, thereby reducing the area occupied by sewage treatment facilities, and reduce residual sewage by maintaining a low sludge load . Amount of mud. It mainly uses membrane separation equipment immersed in an aerobic biological tank to intercept activated sludge and macromolecular organic matter in the tank.

Due to its effective interception effect, the membrane bioreactor can retain microorganisms with a long generation cycle , and can achieve deep purification of sewage. At the same time, nitrifying bacteria can fully reproduce in the system, and its nitrification effect is obvious, providing the possibility of deep phosphorus and denitrification. .

- Treated wastewater indicators

Wastewater indicators

| serial number | project | unit | Allowable value |

| 1 | Turbidity | NTU | ≤20 |

| 2 | pH | 6.8~9.5 | |

| 3 | Calcium Hardness + Methyl Orange Alkalinity

(calculated as CaCO3) |

mg/L | ≤1100 |

| 4 | Total Fe | mg/L | ≤1.0 |

| 5 | Cu2- | mg/L | ≤0.1 |

| 6 | Cl- | mg/L | ≤700 |

| 7 | SO42+ Cl- | mg/L | ≤2500 |

| 8 | Silicic acid (calculated as SiO2) | mg/L | ≤175 |

| 9 | Mg2+×SiO2

(Mg2 + as CaCO3 ) |

mg/L | ≤50000 |

| 10 | free chlorine | mg/L | 0.2~1.0 |

| 11 | NH3-N | mg/L | ≤10 |

| 12 | Petro | mg/L | ≤5 |

| 13 | CODcr | mg/L | ≤100 |

- Process flow diagram

Our company provides customers with customized fusel oil-containing wastewater treatment solutions all year round. The COD content of fusel oil is generally around 3000mg/L, the ammonia nitrogen content is around 400mg/L, and it contains insoluble alcoholic organic matter and trace amounts of phenols and macrocyclic compounds. Difficult to handle.