- business background:

In addition to containing a large amount of formaldehyde, formaldehyde wastewater also contains alcohol, benzene, phenol, parformaldehyde, methylal and other substances. Low concentrations of formaldehyde can inhibit the growth of microorganisms, while high concentrations of formaldehyde can denature proteins, making it difficult for microorganisms to survive.

- Introduction to common processes for formaldehyde wastewater treatment:

- Oxidation method: Oxidation methods include reagent oxidation, ozone oxidation, micro-electrolytic oxidation, strong electrolytic oxidation, photocatalytic oxidation, wet oxidation, ultrasonic/H 2 O 2 method, ClO 2 oxidation method, etc.; the specific process needs to be determined according to the actual situation. .

- Blowing method: Taking advantage of the characteristics of formaldehyde being easily soluble in water, low boiling point and easy to volatilize, the formaldehyde in the production wastewater is pre-treated with steam blowing, which reduces the load of subsequent biochemical treatment and improves the treatment effect.

- Biochemical method: Using formaldehyde as a nutrient for microorganisms, formaldehyde in wastewater is removed through the metabolic decomposition of the organisms themselves.

- Introduction to our company’s process:

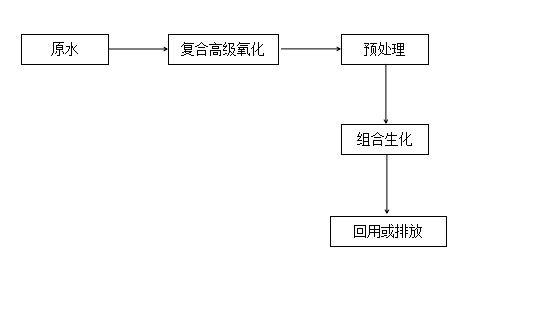

Our company has independently developed a composite advanced oxidation technology that can reduce formaldehyde in wastewater to less than 10mg/l at one time, and then completely degrade formaldehyde through biochemical treatment. This process has the advantages of low operating cost and simple management.

- Wastewater treatment indicators:

According to the latest standard requirements of the “Petrochemical Industry Pollutant Emission Standard” GB31571-2015: the maximum formaldehyde content in the first-level emission standard cannot exceed 1 mg/l. The third-level emission standard cannot exceed 5 mg/l.

- Process flow block diagram:

- Typical projects:

Changzhou ** Chemical Co., Ltd., the production wastewater contains 2% formaldehyde. After being adjusted by the raw water, it enters the complex biochemical process, and then undergoes pretreatment to reduce the formaldehyde to 10mg/l. Then it undergoes biochemical treatment, and the final formaldehyde content in the effluent is less than 0.5mg/l. .

| Indicator item | raw water | preprocessing | Water discharge after biochemical treatment |

| COD (mg/L) | 50,000 | 5,000 | 300 |

| Ammonia nitrogen (mg/L) | 1,500 | 300 | 5 |

| Aldehyde (mg/L) | 20,000 | 10 | 0.5 |